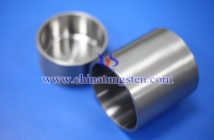

Tungsten crucible is a kind of high-temperature container made of tungsten (W) or tungsten-based alloy as the main material, which is widely used in metallurgy, materials science, semiconductor, aerospace and other fields that require ultra-high temperature treatment. Tungsten is ideal for extreme high-temperature melting and chemical reactions due to its highest melting point of any known metal on the surface (approximately 3422 °C), excellent high-temperature strength, good thermal conductivity, and chemical inertness in vacuum and inert atmospheres.

Using high-purity tungsten powder as raw material, after ball milling, pressing, burning, and then hot isostatic pressing (HIP) densification treatment, the crucible blank with high density and uniform structure is obtained and then machined to obtain W crucible. The use of powder metallurgy molding process for manufacturing has its advantages and disadvantages.

Advantages and challenges

advantage

Extreme high temperature loading: Supports continuous melting and heat treatment above 3000 °C.

High purity and low contamination: Chemically stable in a vacuum/inert atmosphere with no impurities introduced into the melt.

Excellent mechanical properties: low creep at high temperature, strong resistance to thermal shock.

challenge

High cost: Tungsten materials and processing costs are expensive, and the price of crucibles is relatively high.

Easy to oxidize: It will oxidize to WO? at high temperatures in an aerobic environment, and it needs to be used in an inert or vacuum environment, and can be coated for protection.

Difficult processing: powder welding, hot isostatic pressing, machining and annealing processes are strict, and the manufacturing cycle is long.

Future Trends

1. Nanostructure and composite crucibles: through nanocrystalline strengthening, carbide or carbon fiber composite, the creep resistance and oxidation resistance at high temperature can be improved.

2. Additive manufacturing: Explore technologies such as electron beam melting (EBM) or selective laser melting (SLM) to print complex-shaped crucibles and shorten the R&D cycle.

3. Intelligent monitoring: Integrate temperature and stress sensors and AI algorithms to realize online monitoring and life prediction of crucible status.

4. Green manufacturing and recycling: Establish a tungsten crucible recycling system to improve the recycling rate of tungsten resources and reduce the environmental burden.