High-Density Tungsten Alloy, also known as “high-specific-gravity tungsten alloy,” is an alloy primarily composed of tungsten (with a tungsten content of 85–99%) and small amounts of elements such as nickel (Ni), copper (Cu), cobalt (Co), molybdenum (Mo), and chromium (Cr). Its density ranges from 16.5–18.75 g/cm3, more than twice that of steel (approximately 7.85 g/cm3). Depending on the alloy composition, it can be classified into series such as W-Ni-Fe (tungsten-nickel-iron), W-Ni-Cu (tungsten-nickel-copper), W-Cu (tungsten-copper), and W-Ag (tungsten-silver).

In addition to high density, high-density tungsten alloy possesses a range of excellent properties. In terms of strength, its tensile strength can reach 700–1000 MPa, and with special processing, it can even reach 1400 MPa, enabling it to withstand significant stress. In terms of radiation absorption, it outperforms lead of the same volume, making it an ideal material for radiation protection. Its high thermal conductivity allows rapid heat transfer, preventing localized overheating. Its low thermal expansion coefficient ensures relatively stable structure in environments with significant temperature changes. Additionally, it offers good electrical conductivity, weldability, and machinability, allowing it to be processed into complex-shaped components through casting, pressing, and other techniques to meet the needs of various fields.

1. Applications of High-Density Tungsten Alloy in the Medical Field

High-density tungsten alloy is widely used in the medical field, providing strong support for the development of modern medicine, particularly in radiation protection and treatment, where it plays a critical role.

1.1 Robust Shield for Radiation Protection

In radiotherapy equipment, high-density tungsten alloy is key to ensuring radiation safety. For instance, linear accelerators, commonly used in clinical radiotherapy, generate high-energy X-rays or electron beams to destroy tumor cells. However, if these rays leak, they can harm the surrounding environment and personnel. Shielding materials made from high-density tungsten alloy are installed in critical parts of linear accelerators, such as the radiation output port and acceleration tube. With its high density and excellent radiation shielding capabilities, it effectively blocks radiation, preventing leakage and creating a relatively safe treatment environment for medical staff and patients.

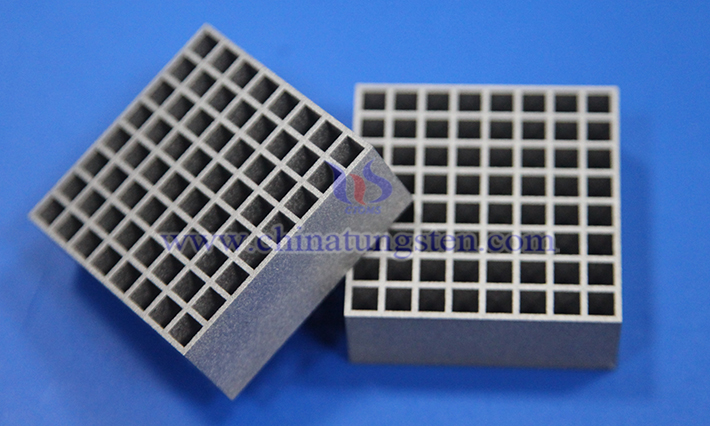

The gamma knife, another important radiotherapy device, uses focused gamma rays to irradiate tumors. High-density tungsten alloy collimators play a significant role in gamma knives, featuring a specific number of holes arranged in patterns such as parallel, focused, divergent, or pinhole types. These collimators enable spatial positioning of gamma rays, allowing rays within a specific direction and angular range to pass through and focus on the tumor site while minimizing radiation exposure to surrounding healthy tissues.

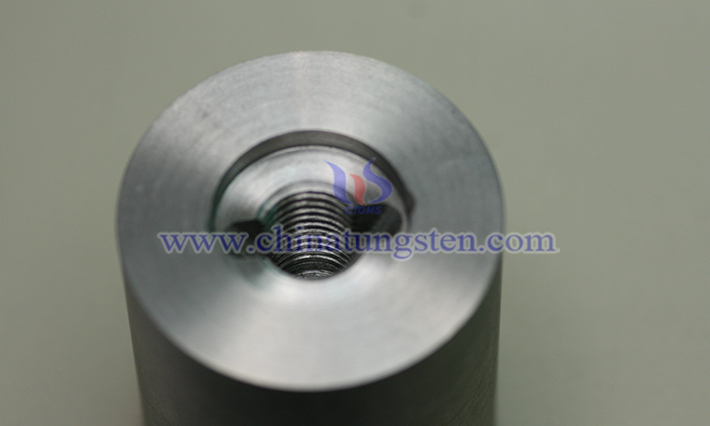

In addition to radiotherapy equipment, high-density tungsten alloy is critical for radiation protection in medical imaging devices such as CT and X-ray machines. CT scanners use X-rays for cross-sectional imaging, generating ionizing radiation during the process. Tungsten alloy collimators are installed between the X-ray tube and the detector: the front collimator shields unnecessary rays, producing a fan-shaped X-ray beam and controlling scan layer thickness; the rear collimator ensures the detector receives vertically incident rays, reducing interference from scattered radiation. This not only improves image quality but also effectively reduces radiation exposure for patients and medical staff. In X-ray equipment, containers made of high-density tungsten alloy for radiation sources effectively block X-rays, providing reliable protection for the radiation source.

1.2 Effective Assistant in Treatment

Radiotherapy is a key treatment method for diseases such as cancer, but minimizing damage to healthy tissues while effectively targeting tumor cells remains a research focus in medicine. Weighted blocks made from high-density tungsten alloy play a critical role in optimizing dose distribution in radiotherapy devices. These blocks are placed on specific areas of the patient’s body surface, designed individually based on the tumor’s shape, size, and location. By adjusting their thickness and shape, they modify the distribution and dosage of radiation, enabling more precise and targeted radiotherapy for tumors.

2. Why Choose High-Density Tungsten Alloy

In the medical field, material selection is critical to equipment performance, patient safety, and treatment outcomes. The widespread use of high-density tungsten alloy in medical applications is primarily due to its significant advantages over traditional shielding materials.

2.1 Outstanding Density and Radiation Resistance

In radiation protection, lead is a commonly used material with a density of approximately 11.34 g/cm3, offering some radiation shielding capability. However, compared to the 16.5–18.75 g/cm3 density of high-density tungsten alloy, lead falls short. To achieve the same shielding effect, lead requires greater thickness than tungsten alloy. In other words, for equivalent shielding performance, tungsten alloy shielding materials require less volume, saving space and enabling more compact equipment designs.

High-density tungsten alloy has strong shielding capabilities against ionizing radiation such as X-rays and γ-rays, primarily due to tungsten’s high atomic number (74) and dense electron cloud. When radiation interacts with tungsten alloy, processes such as the photoelectric effect and Compton scattering are more likely to occur, effectively converting the radiation’s energy into other forms, thus achieving shielding. This robust radiation resistance makes tungsten alloy a reliable choice for radiation protection in radiotherapy and medical imaging equipment.

2.2 Excellent Mechanical Properties

Medical equipment must withstand various mechanical stresses and daily wear during long-term use, requiring materials with excellent mechanical properties. High-density tungsten alloy’s high strength prevents deformation or damage under significant external forces. For example, in gamma knife collimator applications, tungsten alloy collimators maintain stable shape and dimensions during prolonged radiation exposure and frequent equipment operation, ensuring treatment accuracy and stability.

High-density tungsten alloy also exhibits excellent wear resistance. In medical equipment components subject to frequent movement or contact, such as radiation output port components in radiotherapy devices, which endure radiation bombardment and potential mechanical friction, the high wear resistance of tungsten alloy ensures durability, reducing maintenance and replacement costs.

2.3 Outstanding Corrosion Resistance

Medical equipment often operates in environments containing various chemical substances, such as disinfectants and cleaning agents commonly used in hospitals, requiring materials with good corrosion resistance. High-density tungsten alloy can resist corrosion from acids, alkalis, and other chemical media at room temperature, offering a clear advantage over materials like steel, which are prone to rust and corrosion in humid environments. For instance, in medical equipment requiring frequent disinfection, components made from tungsten alloy can effectively resist corrosion from disinfectants, maintaining surface integrity and performance stability, thus extending equipment lifespan.