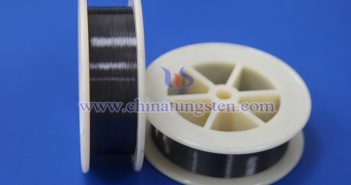

The high strength, high temperature resistance, corrosion resistance and electrical and thermal conductivity of tungsten wire make it irreplaceable in scenarios that require high reliability and durability. The following is an introduction to its main applications: 1. Lighting Industry: Tungsten wire is mainly used for the filament of incandescent bulbs. Due to its high melting point (about 3422°C) and high temperature resistance, it can emit light for a long time at high temperature without melting. In some fluorescent lamps or…