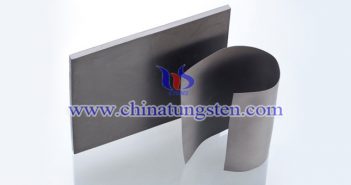

Tungsten alloy medical ray protective material is tungsten-nickel-iron alloy or tungsten-nickel-copper alloy used for shielding medical radiation sources such as X-rays and gamma rays. The difference between the two tungsten alloy materials is that tungsten-nickel-iron alloy has certain ferromagnetism, and its mechanical properties and processing properties are superior to tungsten-nickel-copper alloy. More details, please visit: http://www.tungsten-alloy.com/tungsten-alloy-radiation-shielding.html Tungsten alloy is a new type of medical radiation shielding material that is denser than traditional lead materials. And it is environmentally friendly and…