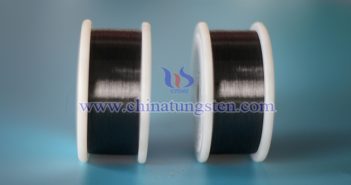

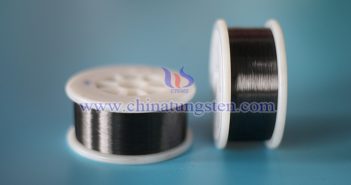

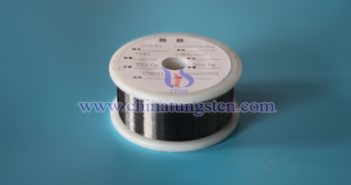

Halogen lamps are high-efficiency and long-lasting light sources, widely used in home lighting, automotive headlights, and stage lighting. One of their core components is tungsten wire, which plays a critical role in the high-temperature environment inside the lamp. The manufacturing process of tungsten wire is complex and generally involves the following key steps: 1. Tungsten Powder Preparation The raw material for tungsten wire is high-purity tungsten powder, which directly affects the final properties of the tungsten wire. Tungsten powder is…