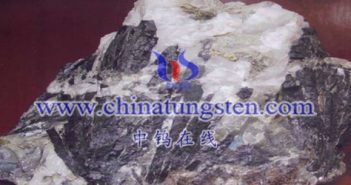

Abstract Since the founding of the People’s Republic of China 70 years ago, my country’s tungsten metallurgy has completed a transformation from scratch, from weak to strong. Especially over the past 40 years of reform and opening up, my country’s tungsten extraction metallurgical theory and technology have continued to develop, and great progress has been made in low-grade complex resource processing, energy conservation and environmental protection in the production process. The early tungsten smelting mainly used the soda sintering method,…