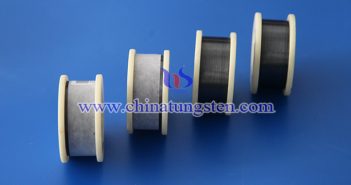

The diameter of tungsten wire is very important in some cases. The metal wire is a common wire material commonly used in light bulbs, electronic devices, thermocouples, heaters, and more. Its diameter determines its physical properties such as resistance value, current capacity, and service life, so the diameter has an important impact on application performance. Here are some situations where W wire diameter needs to be considered: Bulb: the sizes of the tungsten filament are important factors in determining the…